Core Technology

Principles of Maven’s Thin-Film Phosphor Deposition Process

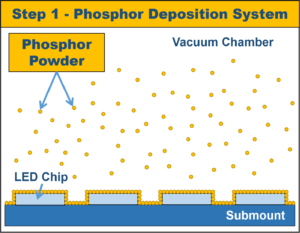

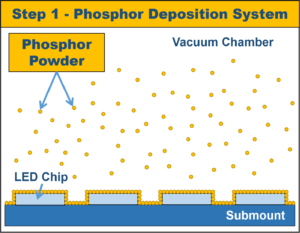

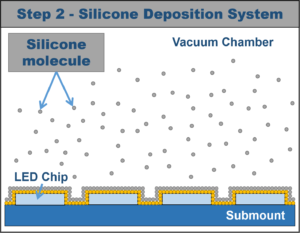

Flow – Controlled PVD Process

- Conformal, thin, dense and uniform

- Precise dosage control

- Flexible phosphor selection

- Phosphor recyclable

- Selective deposition

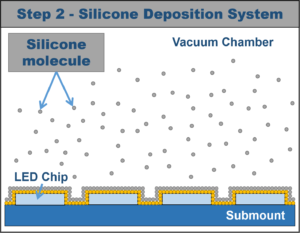

Gap – Filling CVD Process

- Seamless filling

- Moldless forming

- Flexible material selection

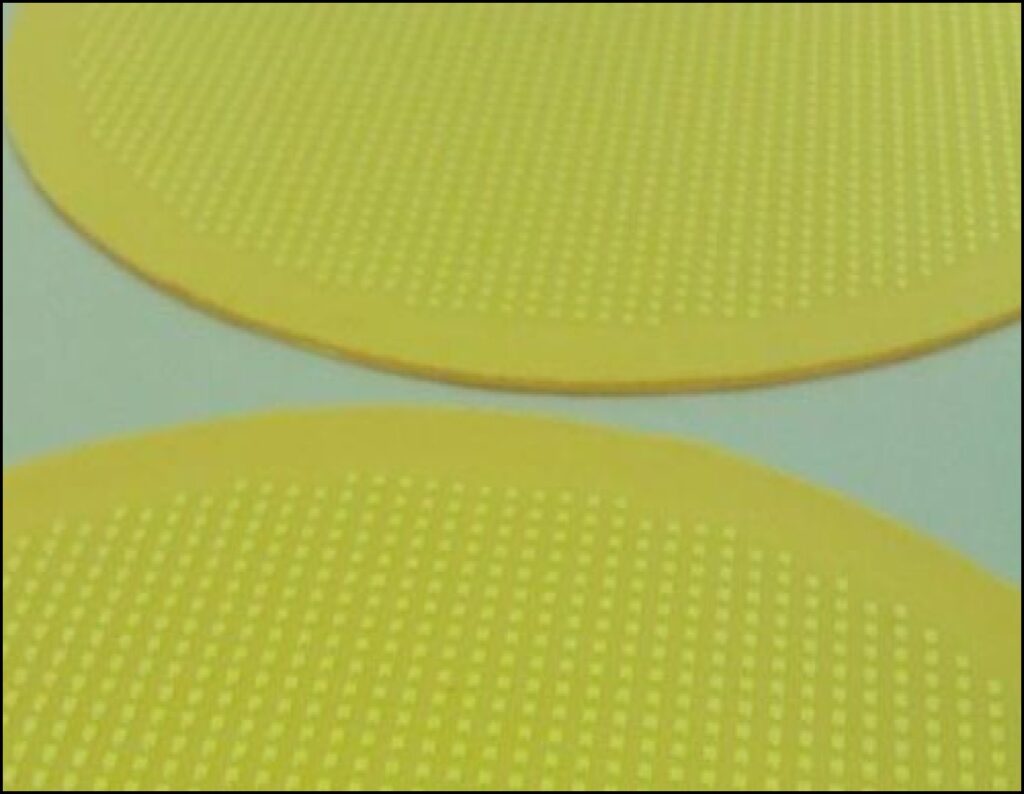

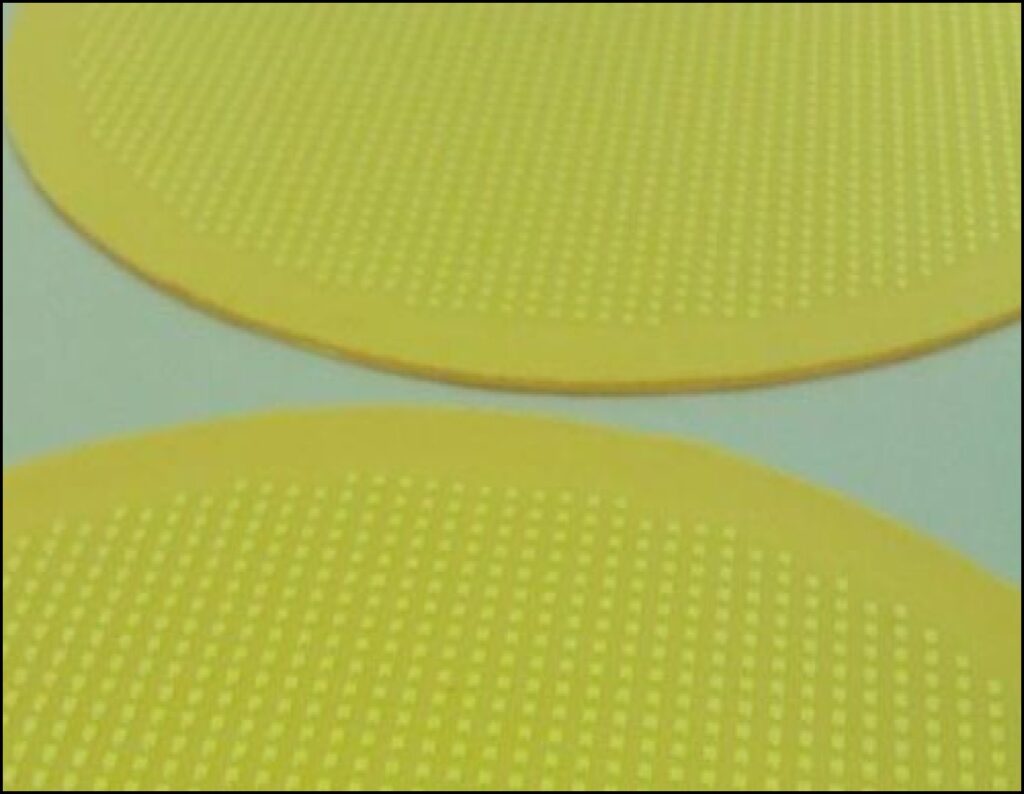

High-density Phosphor Layer

- Layer-by-layer phosphor stacking process

- Phosphor film with good uniformity, high color-conversion efficacy, consistency and reliability

Maven’s Proprietary Manufacturing Equipment

Thin Film Deposition Equipment

- Proprietarily designed and developed thin film deposition equipment

- Better control of the overall cost structure

- Quickly expandable production capacity in response to market demand

Mass Transfer SMT Line

- Proprietarily designed and developed Mass Transfer mounter equipment for Mini LEDs

- High-yield and low-cost SMT line

- Quickly expandable SMT production capacity for Mini LED light board manufacturing